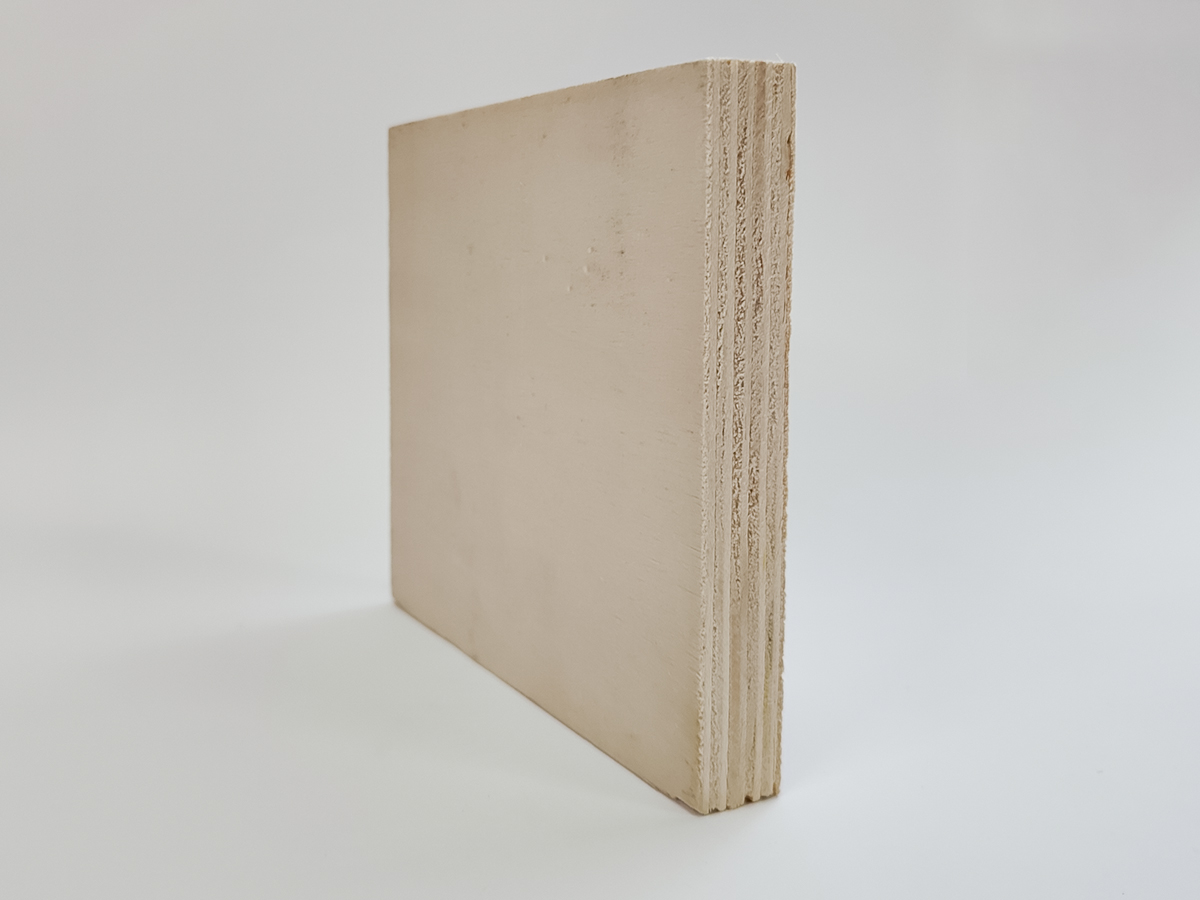

POPLAR PLYWOOD

Poplar plywood is produced by combining the pads obtained from poplar trees. It is obtained from domestic and imported quality poplar trees. Poplar plywood can also be produced optionally from WBP glue.

Poplar plywood can be used in the construction industry, auto interior design, packaging industry, hobby, roofing, machine model mold, caravan and door manufacturing.

Poplar Plywood is used in construction, automotive, auto interior design, roofing, machine model mold, hobby, toy, parquet, packaging, caravan, door manufacturing, wagon, aircraft, and in the ship industries.

Forest Yapı makes its supply for all requested thicknesses. It aims to deliver the right product to its customers at the best possible price.

Poplar Plywood Features

| Dimension | 2500 mm x 1250 mm | 1700 mm x 2200 mm |

| Class | RAW |

| Layer | 3-16 |

| Weight, Kg | 1700 |

POPLAR PLYWOOD TECHNICAL INFORMATION SPECS

Poplar Plywood is used in construction, automotive, auto interior design, roofing, machine model mold, hobby, toy, parquet, packaging, caravan, door manufacturing, wagon, aircraft, and in the ship industries.

| NO | EXPLANATION | FEATURE | |

| 1 | Brand | Various | |

| 2 | Origin | Turkiye | |

| 3 | Tree Type | Pine | |

| 4 | Surface | BB/BB – BB/CP –CP/C | |

| 5 | Dimensions | 2500 mm x 1250 mm-1700 x 2200 | |

| 6 | Glue | WBP | |

| 7 | Intensity | 500-530/m³ | |

| 8 | Thicknesses | 4mm-6mm-9mm-12mm-15mm-18mm-21mm-24mm-27mm-30mm | |

ADVANTAGES OF POPLAR PLYWOOD

- Almost all kinds of lacquers, paints, varnishes etc. are acceptable

- Easy to process in the machine

- It can be supplied in standard sizes.

- Both surfaces are sanded and gauged.

- Absence of imperfections such as knots, cracks or splinters anywhere.

- Having the same density at every point.

- Ready to use.

- Does not require any preparation process.

POPLAR PLYWOOD IMPORTANT INFORMATION

Poplar Plywood is produced from WBP glue and is therefore resistant to boiling water for 72 hours.

The reason why Poplar Plywood is preferred in many areas is its durability, non-shrinking and non-swelling, high mechanical properties and ability to hold nails and screws. It is also easy to process and decorative.

While purchasing Poplar Plywood, it may be beneficial for you to pay attention to the following. Poplar Plywood surface quality should be smooth. One surface should be at least A quality, cracked there should be no knots. The other surface is B quality. A certain amount of cracks and knots are acceptable.

Poplar Plywood;

- Its caliber should be smooth and the thicknesses should be homogeneous superficially.

- The surface should not show any regional thickness differences.

- There should be no margins, if possible, the inner layer thicknesses should be equal.

- There should be no miter misalignment, it may cause problems during side-by-side use.

- The number of layers should be at least 3 layers, the higher the number of layers, the stronger the strength, there is no problem of layering in CNC cutting.

- The water counter must be WBP glued. (phenol formaldehyde)

- If the poplar has started with a tree type, all layers must be of the same tree type, the use of different trees in plywood production creates problems in plywood and this should be taken in consideration while purchasing.

- This should be taken into account when purchasing.

POPLAR PLYWOOD USAGE AREAS

- Furniture

- Boat

- Construction İndustry

- Roofing

- Packaging İndustry

- Container Base

- Interior

- Billboards

- In Caravan Construction

- In Hobby Designs

- In The Making Of Music Columns

- In Machine Model Molds

- It İs Used İn Fields Such As Automotive.